Spin coating is the most advanced technology now used in photochromic lens production. First step before spin coating is substrate cleaning & drying. After that, substrate will go to our spin coating lab. Colloid-like fluid used in spin coating technology is very viscous so spin coating is also known as glue spining. A typical spin-coating process is mainly divided into three steps: Glue dispensing, high-speed rotation and drying( solvent volatilization ), of which the rotation and drying are the most critical steps to control the film thickness and structure. Next step is hard coating which makes the film more wear-resistable and durable. Through years of countless tests and unremitting efforts, spin coating technology used in photochromic lenses ensures an overall qualification rate of 98%. We can provide:

-

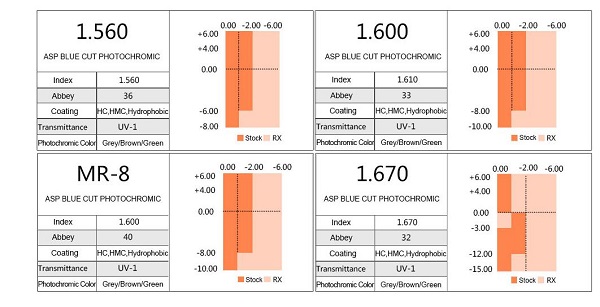

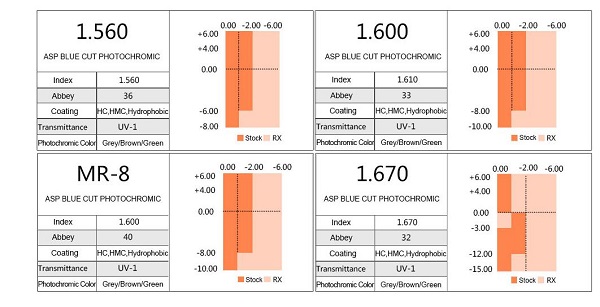

1.56/1.60/MR-8/MR-7/1.74 ASP/SPH

-

Single Vision/progressive

-

Available in grey, brown, green

-

UC/HC/HMC/Hydrophobic

-

Semi-finished photochromic

-

RX lens

All the lenses can do uncoat, hard coated, AR coated (HMC), Hydrophobic coated (SHMC).

Featured product: Blue cut photochromic lens

As we know, blue light has the range of visible light spectrum with wavelengths between 380nm to 500nm which effuse from computer screens, digital devices, LED and natural lights. It will go directly to the retina passing through the cornea and the lens of the eyes,which will cause eyestrain,shortsightedness,blurring of image and other situation.

Our blue cut photo lens takes many advantages

-

It blocks 100% UV light and 90% blue light which are harmful to the eyes & body

-

It reduce burden on the eyes, providing natural and comfortable sight

-

Nearly colorless indoors but darken to maximum tint within 8 seconds when exposed to UV light

-

High transmittance rate without compromising of clear view

-

Super hydrophobic, repels water droplets and oil stains from lens surface

With a daily output of 6000 pairs, we can serve our customers with a varity of items and fast delivery of photochromic lenses, such as blue-cut photochromic, progressive photochromic, polarized lenses. Refractive index ranges from 1.49, 1.56 ,160, 1.67, 1.74. All the lenses can do uncoat, hard coated, AR coated (HMC), Hydrophobic coated (SHMC).